Active in both four-stroke and two-stroke design sectors, Sulzer's links with diesel engine date back to 1879 when Rudolf Diesel, as a young engineer, followed up his studies by working as an unpaid workshop trainee at Sulzer Brothers in Wintherthur, Switzerland. The first Sulzer-built diesel engine was started in June 1898. In 1905 the company built the first directly reviseible two-stroke marine diesel engine and five years later, introduced a valveless two-stroke engine with an after-charging system and spray-cooled pistons. Airless fuel injection was applied to production engine in 1932, and turbocharging from 1954.

Low speed crosshead engine designs from Sulzer, after 1956, were of the single-acting two-stroke turbocharged valveless type emporying loop scavenging and manifested progressively in the RD, RND, RND-M, RLA and RLB series. Details of the RL-type, many of which are still in service, appear at the end of this chapter. A break on that tradition came at the end of 1981 with the launch of the uniflow-scavenged, constant pressure turbocharged RTA series with a single poppet-type exhaust valve.

The original RTA series embraced six models with bore sizes of 380 mm, 480 mm, 580 mm, 680 mm, 760 mm and 840 mm, and a stroke-bore ratio of 2.86.

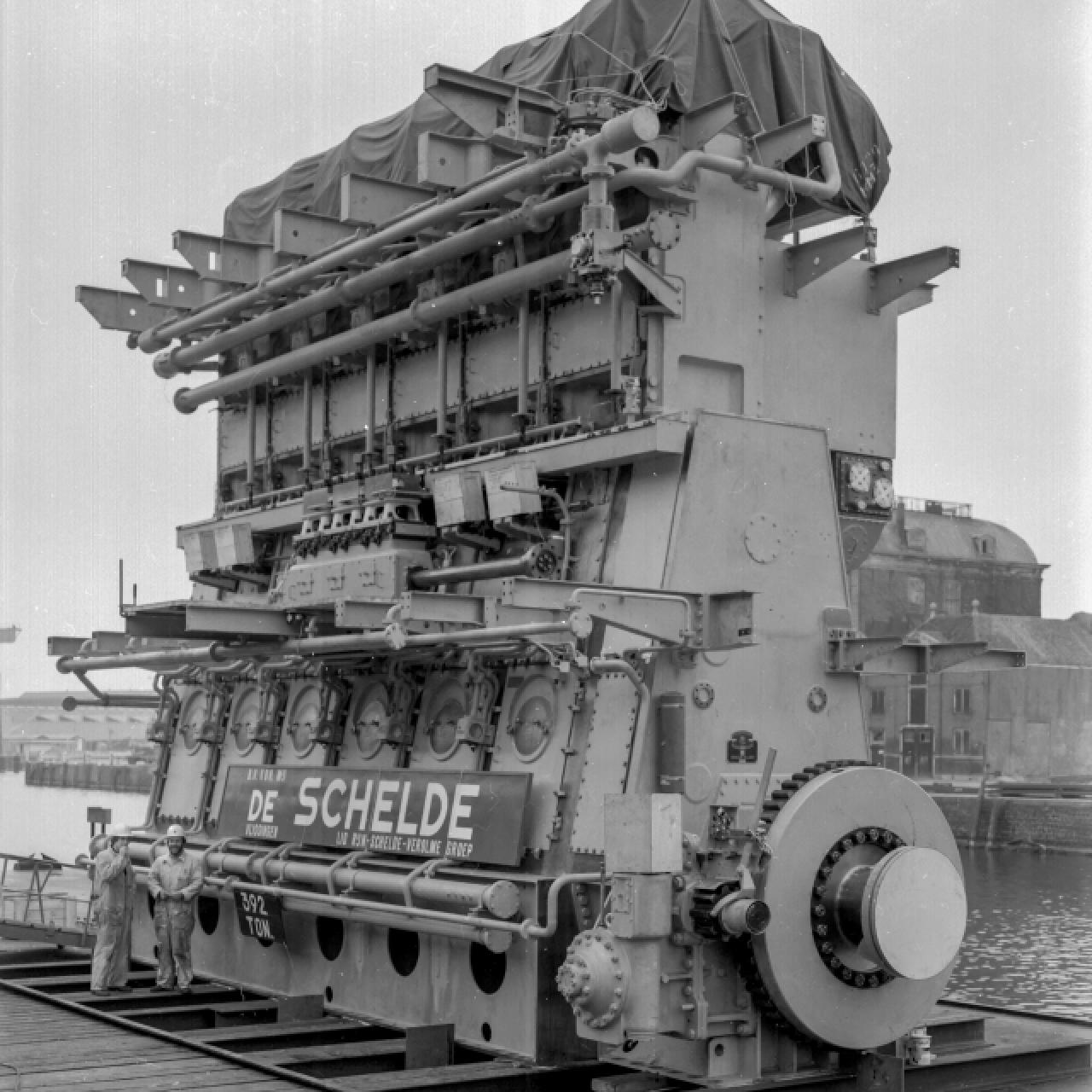

Low speed two-stroke engine designers have invested heavily to maintain their dominance of the mainstream deepsea propulsion sector formed by tankers, bulk carriers and containerships. Only three low speed engine designers/licensors survived into the 1990's to contest the internation arena. Sulzer or New Sulzer Diesel is one of them who build world famous low speed engines for the merchant industry. As Damen Schelde Marine Services is a former licensor from Sulzer / New Sulzer Diesel, our organisation contains a large database of knowledge and know-how about the Sulzer engines.

In 1938 the diesel engine era began when Wärtsilä signed a licence agreement with Friedrich Krupp Germania Werft AG in Germany. The first diesel engine was produced in Turku, Finland in November 1942. During the following decades more focus was put on manufacturing diesel and gas engines with the acquisitions of the Swedish firm NOHAB in 1978, the French Société Alsacienne de Constructions Mécaniques (SACM), and the Dutch Stork-Werkspoor in 1989.

In 1997 Wärtsilä absorbed the diesel motor producing New Sulzer Diesel (NSD), having been created by Sulzer in 1990.

As former Sulzer licensee we have a lot of knowledge about Wärtsilä engine spare parts.

Spare parts for RTA engine series

Premium quality spare parts for the RTA series. All bores are in our scope of supply.

As former Sulzer license holder DAMEN Schelde Marine Services has all knowledge in-house to supply high quality spare parts and maintain these engine types in the best possible way.

Spare parts for RND engine series

As former manufacturer from engine spare parts for Sulzer RND diesel engines DAMEN Schelde Marine Services is a safe harbour for the procurement from spares for these engine types.

Find spares for the following types:

Spare parts for RL engine series

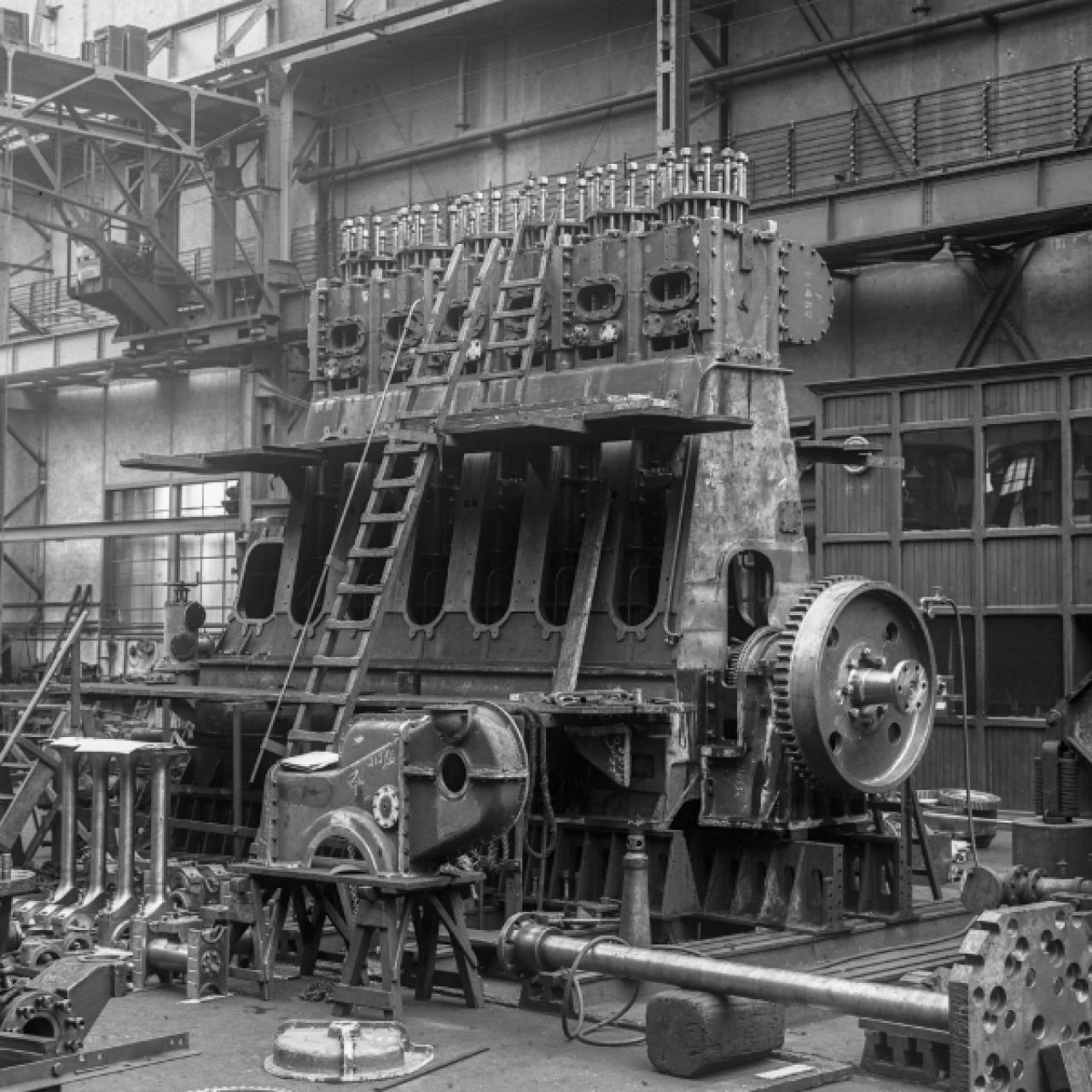

Before RND engine series were introduced DAMEN Schelde Marine Services produced RL engine spare parts and assembled them under license in the factory in Vlissingen, The Netherlands.

Today Damen Schelde Marine Services still supplies high quality spare parts for the following RL series.

Sulzer medium speed engines

When you are in need of parts for Sulzer medium speed diesel engines, also known as the auxiliary engine models, you can find parts for the following types in our assortment: S20, S20U, S20UH, ATL and ASL

Damen Schelde parts is able to offer most common wear and tear parts for these type of engine such as cylinder liners, bearings, plunger and barrels, fuel equipment, pistons, piston rings, bolts, nuts, screw, gaskets and complete kits.

Send us an inquiry by email, chat with us or connect with us on whatsapp

Premium quality

With our routes in producing engines and parts for marine diesel engines we know how to produce quality and understand the needs from the customer. By having our own in-house quality control department and our ISO certificate we strive always to deliver the highest possible quality to meet the specifications from the maker.

Moreover, we strive for an optimal product that meets customer expectations. And we provide services to deliver a full service package. Close cooperation with customers with a specific engine ensures the best of both worlds in products and services.

The following systems and procedures are in place to support our aim of totally unburdening the client and satisfy the customer:

- ISO 9000/2015

- In-house quality department

- Training and development for our employees

- Offer and supply with relevant certificate if applicable

Our internal procedures are regularly reviewed both internally and externally to ensure we provide our customers with the best products - on time and with the right quality.

Support and advise

Having an important role for the client by support on their engine we understand the importancy of keeping the vessel in service. Our service and support on an inquiry goes further than only giving a price.

- We advise the client with the latest possible standard for the item in terms of execution. We intend to have for example all parts suitable for the new fuel standard.

- In our database we store previous made and offered executions from parts such as nozzles (atomizers), cylinder heads, pistons, turbochargers, air coolers and all other relevant items that contain an IMO marking.

- We check where the vessel is and customize the offer to the location from the vessel. We can offer from Europe or make the offer from our locations in Asia.

- If the items are not yet confirmed in our system with an specific execution we check with the client what they need. Once having that clear we store such information in our ERP system. That makes us not ask twice if the items needs replacement in the future.

- In some cases the vessel will change from owner and Damen Schelde parts have stored all delivered items and executions in the ERP system. We have more then 9.000 vessels registered in our database.

Services for Sulzer RTA/RND/RL engines

Download our brochure

|

DAMEN Schelde Marine Services Company brochure 1,00 MB |