About piston rings

A piston ring is an expandable split ring used to provide a seal between the piston and the cylinder wall. Piston rings are commonbly made from cast iron. Due to the new sulphur cap 2020 regulations MAN B&W have introduced cermet coated piston rings. For older types or engines that use for example scrubbers and keep running on HFO we have types such as aluminium, bronze and ceramic coated versions.

Other options are piston rings with gas tight lock and left-hand, right-hand executions and models with different dimensions such as 9, 11, 12,5 and 14 mm.

Piston rings in a marine diesel engine

Similar to other types of internal combustion engines, a marine diesel engine operates with three or more types of piston rings. The smooth and efficient operation of a marine diesel engine relies heavily on the secured sealing of the piston rings liners.

Functions of marine diesel piston rings

In general there are four functions known that piston rings fulfill.

Compression gas seal; Compression piston rings guarantee that there is limited leakage, which can result in decreased gas compression pressure. A leak in gas compression will lead to insufficient power to fuel the engine and a significant increase in fuel consumption.

Lubricating oil; Piston rings also spread the lubricating oil as it moves up and down the cylinder liner thousands of times per minute. This makes the piston operate smoothly, reducing the risk of friction and scuffing between metal parts

Heat regulation; During gas ignition, the temperature inside a piston can go up to 300°C. If this goes further, intense undistributed heat can damage the engine. Piston rings help regulate the temperature inside by releasing the transferring heat from the piston crown to the cylinder.

Form a barrier; A piston ring acts as a barrier between the piston and the cylinder wall, which prevents frictional force and eventually engine failure.

Damen Schelde Marine Services has been contributing to the shipbuilding industry throughout the world for over 140 years as former manufacturer and supplier of internal combustion engine components including piston rings.

In particular, the piston rings for marine use internal combustion engines, boasting high quality and performance have been held in high repute among worldwide users. The piston rings are based on specifications that are standardized by the original engine manufacturers and exist out of many different materials of special cast iron and coatings.

The production of a piston ring is based on the following processes from tapping, machining, rough grinding, cutting-off GAP and further treatment starting with plasma spray, side surface finish, gap sizing and ending up with marking the parts.

Composition of piston rings

Our piston ring programme contains different compositions of material. Several factors are important and related to different chemical compositions. For example size, value of modulus of elasticity, value of transverse test strength, hardness and coefficiten for detoriation of tension. These factors are all applicable to the known Cast iron executions such as Nodular Graphite, Compacted Vermicular Graphite and Flake Graphite.

Configuration of marine piston rings

Within these configurations we split the cross-section types in compression rings and oil control rings. When talking about compression rings we have the following types:

| Type | Application and features |

|

Plane |

Basic geometry of compression ring |

| Grooved | Effective for retaining lubrucation oil |

| Tapered face | Effective for controlling the oil film on the cylinder wall |

| Tapered balance undercut | Used mainly as the lowest stage pressure ring of 4 stroke diesel engines |

| Symmetry barrel face | Prevents edge loading during the initial run-in operation |

| Internal bevel barrel face | Feature a twist effect |

| Asymmetry barrel face | Effective for facilitating the initial run-ing operation |

Oil control rings are known to us in the following configurations:

| Type | Application and features |

| Cutter | Ordinary oil ring geometry |

| Bevel cutter | Smaller rubbing surface to enhance oil control capability |

| Bevel cutter | Effective for suppressing the reduction of surface pressure due to circumferential wear |

| Bevel cutter with coil | Greater oil control capability using a coil expander |

| Bevel cutter with coil | Used for reducing lubrication oil consumption for medium-size, medium-speed diesel engines |

| Bevel cutter with coil | Permits larger coil diameter for larger tension |

Besides the shape of the rings for the configuration it is also relevant what shape of joints are used depending on the application and wanted features. Below we describe the types.

Butt joint; mostly used in relatively large size engines

Right angle joint and Left angle joint; Used in low speed engines and hydraulic equipment

Double ange joint, Double round joint and Double step joint; In order to give gastight state at joint, these types are used for hydrualic cylinder and large size, low speed engine

Surface treatment for marine use rings

Plating are known with the following films

- CPN

- Cr

- RQBM

- CPC

Sprays are known with the following films

- Ceramic;

- molybdenum and Ni-Cr;

- Cu; and

- Graphite-Cu-Sn

Would you like to know more about Cermet piston rings for MAN B&W two stroke engines Read more

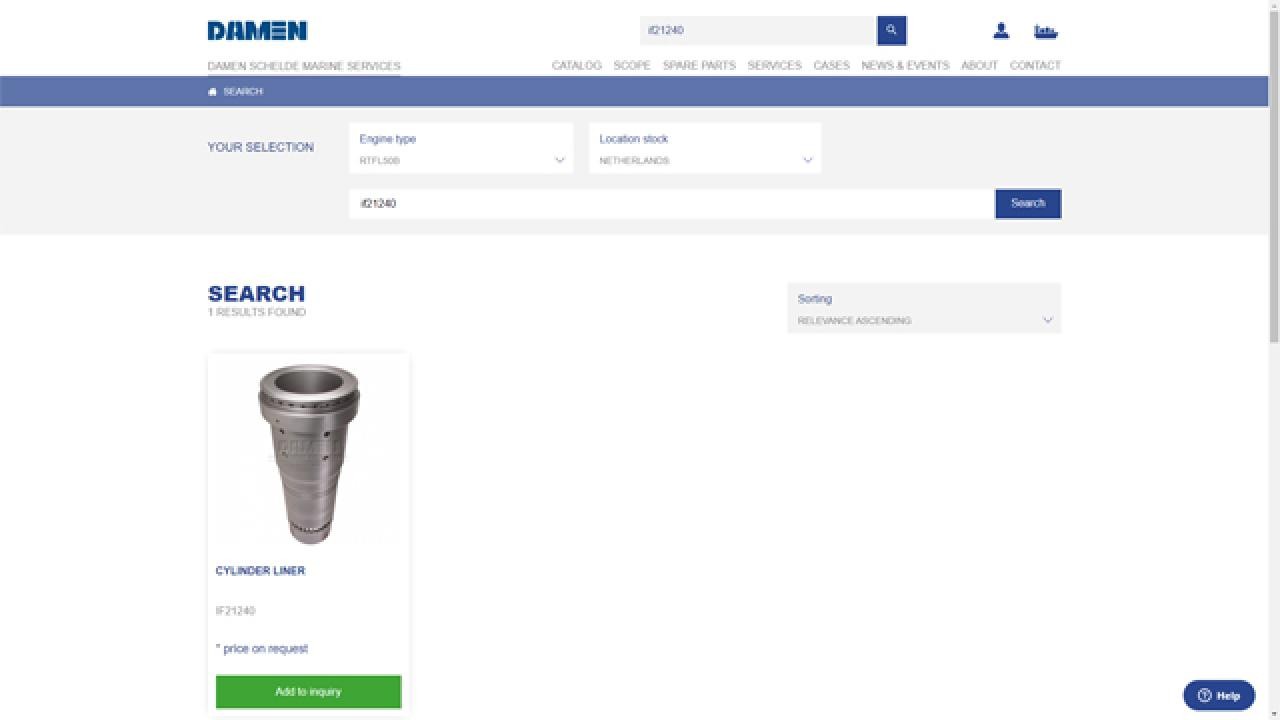

Search in our online catalog

With over 250.000+ parts in our catalog you are able to search in our database.

- For Sulzer/Wärtsilä two and four stroke engines,

- MAN B&W two and four stroke engines

- Yanmar and Daihatsu four stroke auxiliary engines.

- And many brands that are located on the engine such as Emerson-Aventics, Bosch-Rexroth, Trafag, Boll & Kirch and many more.